We offer SMT and through-hole technology that exceeds expectations, and our manufacturing process is validated at every phase.

Printed Circuit Board (PCB) Assembly

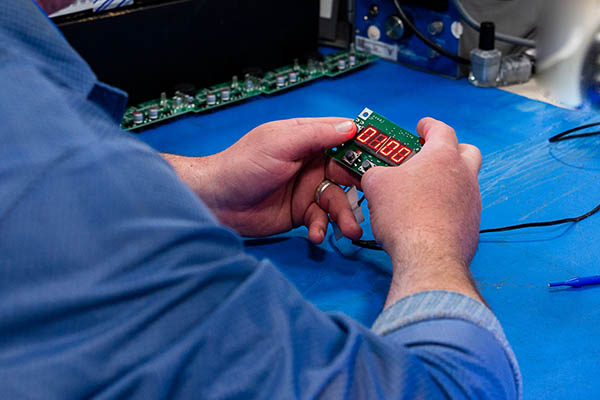

At RW Technologies, we offer mixed technology of both surface mount technology (SMT) and through-hole technology that meet or exceed the international standards of IPC-A-610 and ISO 9001:2015 Quality Management Systems Requirements.

However, we do much more than circuit board manufacturing. We help ensure that your circuit boards will function properly in the field by validating at every stage.

USA Printed Circuit Board Assembly (PCBA)

Other companies that assemble circuit boards outsource overseas to China or India for their manufacturing. Some US companies even outsource overseas, and claim they don’t!

By contrast, our highly skilled circuit board technicians assemble all your printed circuit boards right here in the United States. In fact, every step of our US-based circuit board assembly process takes place in Crystal Lake, IL—northwest of Chicago.

Our High-Quality Circuit Board Manufacturing Process

How is our process unique from other printed circuit board assembly?

Many others who assemble circuit boards will take a circuit board schematic or layout and immediately produce it. The boards arrive, and they don’t function. They overheat. They catch fire. Or they simply don’t work as intended.

We’re different. In our circuit manufacturing process, we can help you at a variety of stages:

DESIGN

- Validate your electronics idea (even if you have no design or circuit board schematic).

- Use your schematic to generate your layout.

- Create your circuit board layout from a schematic, or use a layout you provide.

Next, we: - Provide a design-for-manufacturing review. (Validate your layout for manufacturing.)

- Offer options to source parts for you, or use your provided components.

- Assemble your printed circuit board

- Build a circuit board enclosure, as needed.

- Validate again.

- Produce or mass produce your high-quality, functioning circuit board in our US facility.

FAST & EFFICIENT

You might assume that all this attention to meeting high-quality standards might dramatically slow circuit board production. Not true.

At RW Technologies, our circuit board assembly process is efficient, fast, and smooth.

FLEXIBLE

Our Printed Circuit Board Assembly Is flexible. Flexibility is vital. Our production schedules are always subject to short notice change. In other words, if you need to make changes on the fly, we can almost always accommodate your request without additional charges, unlike overseas production facilities.

THE TECHNOLOGY

Mixed Technology Circuit Board Assembly Capabilities

We offer mixed technology—both SMT and through-hole technology. We can meet RoHS compliance for PCB fabrication, components, and assembly process. Among other proficiencies, our capabilities include:

- Lead-free assembly (PCB fabrication, components and assembly processes)

- Automated optical inspection (AOI)

- Printed circuit board (PCB) thickness from as small as 0.4mm to as large as 5mm

- Radio frequency (RF) and microwave assemblies

- Light emitting diode (LED) circuit boards

- Camera modules for the telecommunications industry

- Fiber optic tranceivers

- IPC-A-610, Class 1, Class 2 and Class 3

Surface Mount Technology – SMT

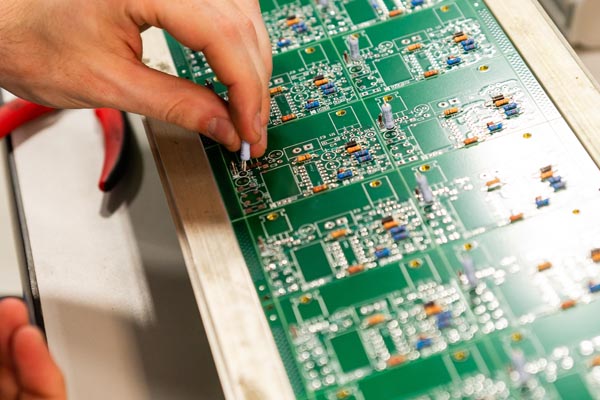

New jobs are set up offline. Once pick-and-place (P&P) and automated optical inspection (AOI) programs are optimized, our data is centrally stored. This helps to guarantee the correct program and vision information is loaded every time. What’s more, our machines are easily optimized for products with up to several hundred unique line items.

Our SMT’s capabilities include:

- 0.35mm pitch quad-flat no-leads (QFNs), quad-flat packages (QFPs) and connectors

- 0201 passive circuit board components

- Ball grid arrays (BGAs and µBGAs)

- Chip-scale packages (CSPs)

- Fine pitch quad-flat no-leads (QFNs)

- Fine pitch devices and connectors

In addition, RW Technologies’ experienced engineering and manufacturing teams always:

- Develop custom reflow profiles for all leaded and RoHS-compliant printed circuit board assemblies (PCBAs).

- Review solder stencils in detail.

- Carefully develop any additional tooling or fixtures required to optimize the process for each individual assembly.

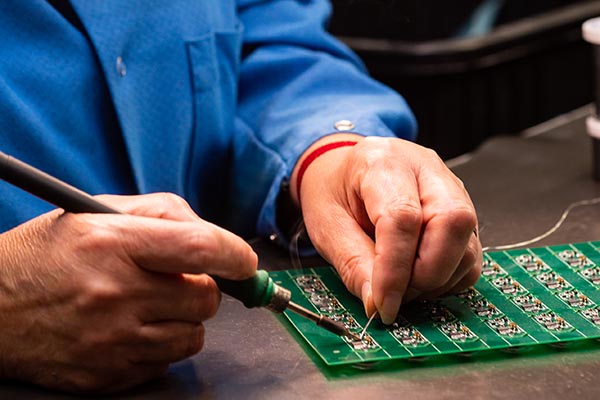

Through-hole Technology

We make color-coded assembly drawings, which reduces assembly errors and increases efficiencies in the build process. This saves you money. Our through-hole capabilities include:

- Selective soldering

- Wave soldering

- Hand-soldering